Frontiers of Plasmatrons

New data on plasmatron electrode erosion have been obtained for a wide range of materials in various gas media on the basis of comprehensive research of plasma-arc processes. A series of technological melting plasmatrons has been developed for integrated processing of technogenic wastes

The service life of each plasmatron is determined by the operation time of its electrodes, which depends on the electrode material erosion intensity in the zone of current transfer from the gas-discharge plasma with the temperature range from 10,000 to 20,000 ° С to the electrode metal (or, as researchers say sometimes, under the arc “spot”). Electrode erosion is induced by the high heat-flux density reaching hundreds and thousands of kilowatts per square centimeter of the electrode surface, by chemical interaction with the plasma-forming gas, and by thermomechanical stresses caused by thermocyclic loading. These factors make it rather difficult to solve the problem of electrode failure. Investigations of near electrode processes in arc-jet discharges performed at the Khristianovich Institute of Theoretical and Applied Mechanics of the Siberian Branch of the Russian Academy of Sciences are aimed at elucidating the electrode erosion mechanisms and developing counteractions to prevent electrode failure. New knowledge has been obtained on erosion of a wide range of materials (bronze, brass, precipitation strengthened copper, copper and silver alloys) in oxidizing, reducing, and neutral gas media

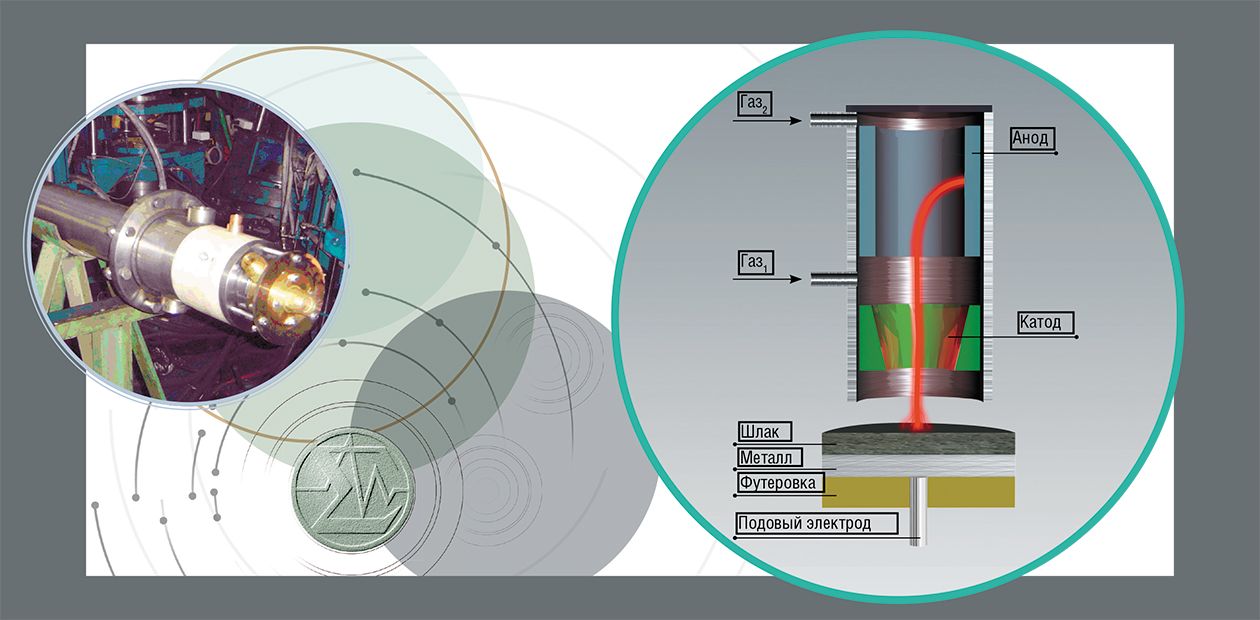

In addition, a lot of attention is devoted to plasmatron applications in developing plasmathermal technologies of processing and neutralizing industrial and domestic solid wastes. In this context, d.c. electric arc plasmatrons are used for remelting and refining various metals, extracting and accumulating of valuable components from industrial materials, and vitrifying inorganic elements of domestic, medical, industrial, and weakly radioactive wastes.

Plasmachemical processing of man-caused wastes involves gasification of their organic components with neutralization of hazardous species and melting of their inorganic components with formation of chemically inert lustrous slag. A typical facility for such a processing technology contains a chamber for gasification (incomplete combustion) of organic waste components, an afterburner of effluent gases, a melting chamber with a plasmatron, systems for melt unloading and cooling, and a system for fume cleaning.

These technologies are mainly based on using melting arc plasmatrons. Based on investigations of near-electrode processes, durability of electrodes made of various materials, and effects of gas dynamics and electrode geometry on the degree of their erosion, a series of air-driven melting plasmatrons with the power range of 150—1,000 kW, operating arc current up to 1,000 A, and life time of at least 1,000 hours was developed.

The industrial series of plasmatrons developed at the institute is currently used in Russian industries to extract platinum from catalysts of afterburning units in cars and to utilize wastes containing metals and plastics, as well as in some cities of South Korea to process asbestos-containing, medical, and domestic wastes.

References Lukashov V. P., Vashchenko S. P., Bagryantsev G. I., and Pak Kh. S. Plasmathermal processing of solid wastes // Ekologiya i Promyshl. Rossii. 2005. No. 10. P. 2—7.