On the Way to the Detonation Engine

Uncontrollable transition of turbulent combustion to detonation is a plague on all types of internal combustion engines. The use of a controlled continuous process of generation of detonation waves as the basic element of such engines provides a qualitatively new result…

Many of us have been frightened from time to time by a loud “clap” in the engine of a car passing by. This clap is caused by detonation. Unpredictable emergence of detonation (or almost explosion) in combustion chambers of all types of engines and power facilities with subsequent burnout and failure of structural elements poses the following question: Is it possible to organize this process properly and use its benefits instead of trying to quench the detonation (explosive) character of combustion?

It is not a secret that a significant portion of unburned fuel is ejected into the atmosphere when a supersonic velocity is reached, for instance, in air-breathing engines of flying vehicles and in all commercial internal combustion engines that involve turbulent combustion (actually, no other engines are available). The environmental hazards of this process are obvious. Extremely poisonous additives-antidotes used for detonation quenching aggravate the degree of contamination.

For this reason, attention of scientists all over the world is riveted to the problem of stabilization of detonation combustion.

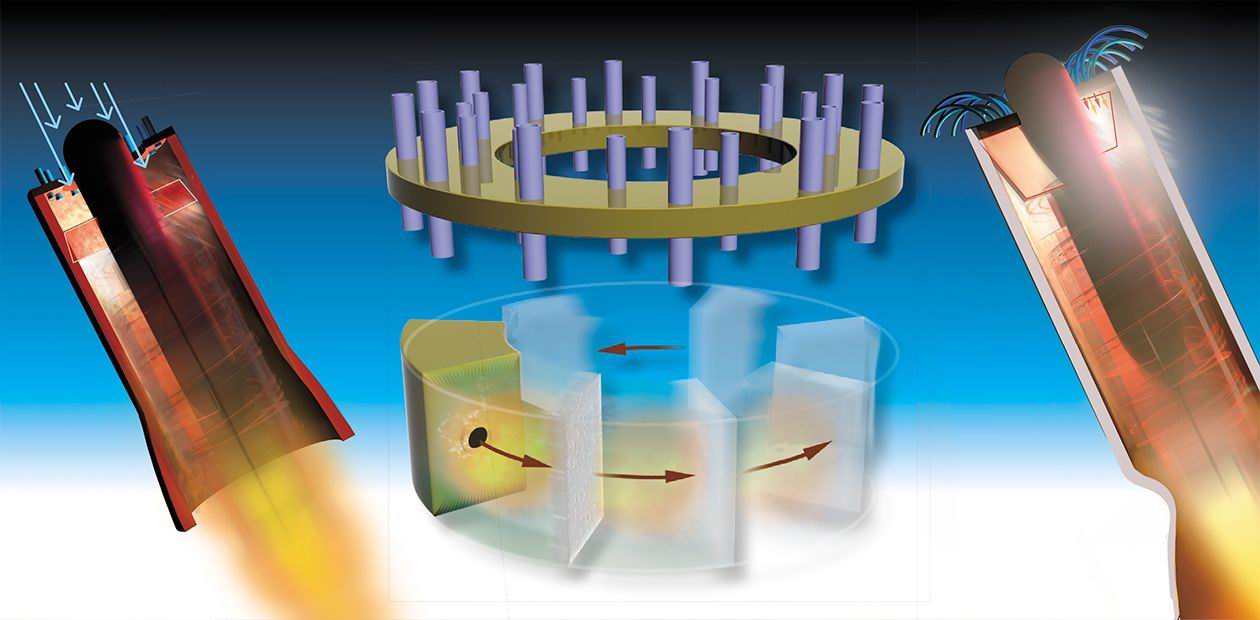

Concerning the organization of combustion of the fuel mixture in a transverse detonation wave (TDW), i. e., a “spin” detonation wave, the priority in solving this problem belongs to Russia, in particular, to the Lavrentyev Institute of Hydrodynamics of the Siberian Branch of the Russian Academy of Sciences. B. V. Voitsekhovskii was a pioneer in burning acetylene-oxygen mixtures in the transverse detonation wave in controlled continuous detonation conditions [1]. After conducting these experiments abroad, he received several foreign patents on using continuous detonation combustion conditions in rocket engines.

In other words, the phenomenon that had been considered hazardous for many years (many attempts had been made to avoid it) became an integral element in designing a new type of internal combustion engines. The theoretical priority belongs to Ya. B. Zel’dovich, who was the first to study the possibilities of using detonation combustion of fuels in power engineering [2].

Zel’dovich demonstrated that detonation combustion of fuels occurred with a smaller increase in entropy of combustion products and, hence, with a higher kinetic energy and with lower thermal loads. There is no need to fight against the “claps,” because the noise effects and vibrations in the detonation combustion chamber with a specially developed structure are not higher than those during the operation of a conventional internal combustion engine.

The advantage of detonation combustion in particular devices is the smaller size of the combustor determined by the size of the detonation wave. This results in more intense and complete combustion of a wide class of fuels with entrained detonation products and ensures a higher thrust produced by the engine.

The authors demonstrated the use of a unique photorecorder, which makes it possible to “freeze” the processes of the microsecond time scale, which occur in the TDW region for a long period of time (up to 1 second). A Russian patent on the method of fuel burning has been issued [3].

What the frozen flame looks like

What can burn in spin waves, why, and how? A reasonable question arises: if cut up by rigid fronts of continuous spin detonation, will the mixtures of conventional types of fuels and oxidizers ever burn under these unusual conditions? If they do burn, will the burning be stable, continuous, and effective? To answer this difficult question, hundreds (if not thousands) of experiments and calculations were performed, many drawings for versatile design concepts were made, and numerous modifications of combustion chambers were made in iron, such as ramjet-type engines and air-breathing engines.

The results exceeded all expectations, though labor-consuming, careful, and often routine studies had to be done. It was found possible (with a proper arrangement of the process, which is a know-how) to burn effectively almost all conventional gaseous or liquid hydrocarbon fuels mixed with gaseous oxygen, air, and liquid oxygen as oxidizers under these tough conditions.

It became possible to predict and observe (which does not happen often) an unusual effect of the transonic transition in the flow with an invariable cross-sectional area, which is not observed in an ordinary combustor not contoured for supersonics. The pressure in the chamber in the zone of transverse detonation waves oscillates with the frequency of TDW rotation, reaching the maximum values in the front approximately 3 to 5 times higher than the mean pressure under usual conditions.

When a person rapidly climbs up a hill, he feels his heart beating faster. Similarly, for a supersonic liner not to have a “heart attack,” not to burn within several seconds due to intense heating, and not to disintegrate owing to “fibrillations” when climbing in the atmosphere, it is necessary to determine the range of existence of a stable periodic and continuous spin TDW, which is the heart of the engine. This range was found by varying the difference between the pressure in the combustor and the ambient pressure, which determined the region of standard safe conditions. It was interesting that a stable continuous spin detonation process in the combustor with channel expansion could occur even if the pressure in the combustor was lower than the ambient pressure. The quality of mixing was found to produce a significant effect on the stability of the TDW velocity and its structure (except for the moments when the number of TDWs was changed) in a wide range of the ratios of the components and the differences in pressure between the combustor and the ambient medium [3—5].

Changes in the ratio of concentrations of the components of the combustible mixture, configurations of fuel injectors, and pressures inside and outside the combustor lead to changes in the TDW velocity, formation of complicated mode of superposition of 1-2-3 and more undulatory structures, as well as to their decay, and to the amplification and change in the spin rotation frequency.

The knowledge obtained is quite indispensable, first of all, for the developing of new types of engines for various flying vehicles.

Epilogue, optimistic but always sad

If an architect constructed a house based on the principle “live in what you have drawn,” the house would collapse sooner or later, though theoretically it could stay forever. Many people do not know that theoretical calculations are followed by creating a mockup from different materials, which is then placed with its basement in various soils and subjected to various intense tests in order to postpone its collapse for the longest possible time. Airplanes and space vehicles experience much more intense and versatile loads which are incommensurable even with natural disasters.

The incommensurable cost of these two projects, which have to be safely protected from external and internal “disasters” and which could be possibly compared only in scales (“Earth house” and “space rocket”), reflects their incommensurable complexity. The first project can be financed by a moderate-size group of individuals who do not even have to be millionaires, while the second project can only be financed at the governmental level. Large investments in such projects taking place in competing foreign states means that Russia needs to make investment of comparable scale in due time.

References

1. B. V. Voitsekhovskii. Steady detonation // Dokl. Akad. Nauk SSSR. — 1959. — Vol. 129. — No. 6. — Pp. 1254—1256.

2. Ya. B. Zel’dovich. On the use of detonation combustion in power engineering // ZhTF. — 1940. — Vol. 10. — No. 17. — Pp. 1453—1461.

3. F. A. Bykovskii, B. V. Voitsekhovskii, V. V. Mitrofanov.Method of fuel combustion, Patent No. 2003923, Claim No. 4857837/06 dated 06.08.1990 // Bul Izobr., 1993. — Nos. 43—44.

4. F. A. Bykovskii. High-speed waiting photorecorder // Zh. Nauch. Prikl. Photogr. Kinematogr. — 1981. — No. 2. — Pp. 85—89.

5. F. A. Bykovskii, S. A. Zhdan, E. F. Vedernikov. Spin detonation of a fuel-air mixture in a cylindrical combustor // Dokl. Ross. Akad. Nauk. — 2005. — Vol. 400. — No. 3 — Pp. 338—340.