Optical Сleaning of Lithium Niobate

Researchers from the Institute of Automation and Electrometry of the Siberian Branch of the Russian Academy of Sciences (Novosibirsk) and from the University of Bonn (Germany) proposed and implemented a new technology of eliminating the effect of optical damage for lithium niobate crystals which is called the method of optical cleaning

By analogy with semiconductor materials, lithium niobate crystals (LiNbO3) are often called the silicon of photonics. They are indispensable and promising in many fields of modern optics: for transformation of light frequency, modulation of laser radiation, and development of optical memory devices and functional microresonators. The reason for that is a unique combination of important properties inherent in these crystals: growing simplicity, low cost, reliability, transparency in a wide spectral range, high nonlinear-optical coefficients, etc. Thousands of publications deal with lithium niobate properties, and their number continues to grow rapidly.

The main obstacle for using lithium niobate in many optical devices is the effect of optical damage (light beam failure), which has been known since the 1960s. This spurious phenomenon has the following cause: under the action of light, a moderate amount of photoactive electrons moves toward the axis of symmetry of the crystal, thus inducing the emergence of strong electric fields and associated changes in the refractive index. The possibility of optical damage suppression has been intensely studied for the last 10—15 years. Today the best solution is assumed to be the introducing of magnesium admixtures into lithium niobate crystals, but this method is expensive and inconvenient.

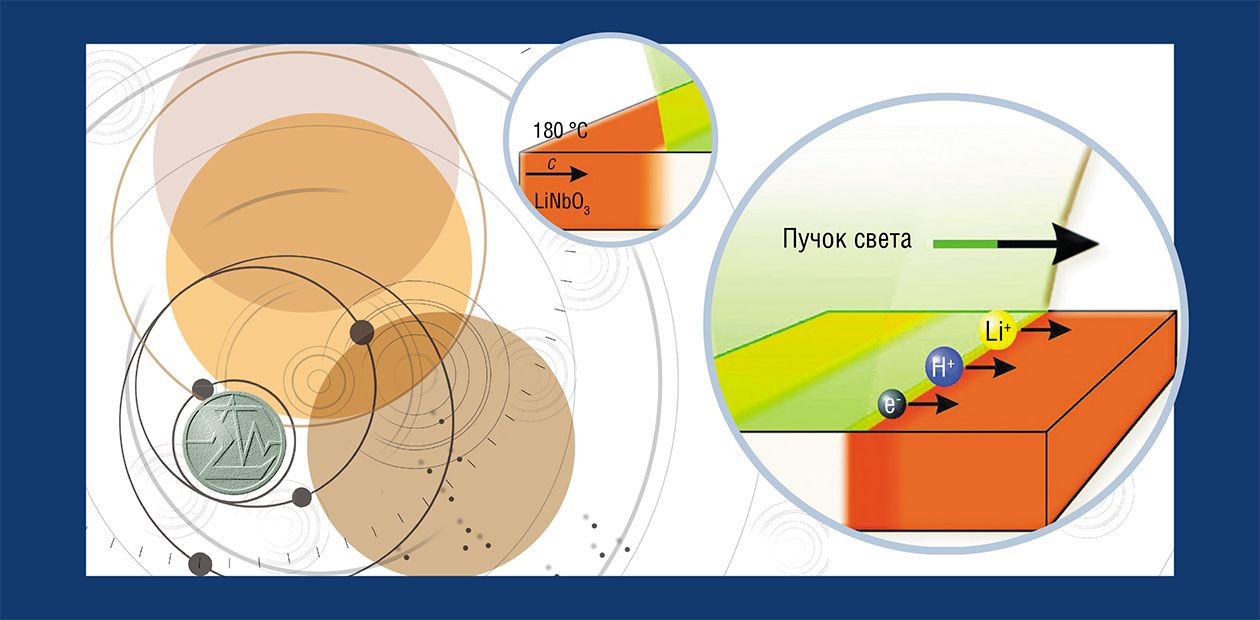

A new technology was proposed and implemented to eliminate the effect of optical damage. This technology was called the method of optical cleaning. The crystal is heated to a temperature of 170—190 ° C, after which it is illuminated by a fairly intense light beam.

The method is based on the same photovoltaic effect that was previously considered an adverse effect generating optical damage. Now it is used as a beneficial effect: in the exposed area, photoactive electrons move along the crystal axis and become accumulated at the periphery of this area. If the moving particles were electrons only, at the place of their accumulation there would appear an electric charge which would prevent further accumulation of particles. To avoid this, positively charged particles available in the crystal, i.e. hydrogen ions (protons) and lithium ions should follow the electrons. The number of positively charged particles exceeds the number of photoactive electrons by several orders; still, it is not sufficient to affect the crystal properties.

Crystal heating is needed for the ions to acquire a fairly high mobility and to move behind the electrons. The crystal proper remains electrically neutral at each particular point.

Thus, under the above-described conditions the exposed area with time becomes completely free from photoactive electrons. If the light beam moves slowly in the direction of photoactive electrons, the entire crystal is cleaned from them. As a result, the optical damage source is naturally eliminated. After the crystal has cooled, the moved electrons cannot return to the cleaned area, because they are stuck with the frozen ions. The cleaning result is a strong (by more than a factor of 1,000) suppression of optical damage.

Experiments show that the optical cleaning process at the moment takes many hours, which implies that further efforts have to be made for its optimization.

The optical cleaning effect is also interesting from the viewpoint of basic research. The process of local reduction of the photoactive electron concentration by a factor of thousands or tens of thousands by means of light beam application has no analogs and leads to significant changes in material properties. A similar effect is expected for other optical materials whose symmetry is similar to that of lithium niobate.

Kösters M., Sturman B., Werheit P. et al. Optical cleaning of congruent lithium niobate crystals // Nature Photonics. 2009. V. 3. P. 510—513.

Sturman B., Kösters M., Haertle D. et al. // Phys. Rev. B. 2009 // V. 80. P. 245—319.