Titanium-Strength Bite

At the XII International Exhibition of Industrial Property entitled «Archimedes–2009», the Institute of Strength Physics and Materials Science of the Siberian Branch of the Russian Academy of Sciences (Tomsk) was awarded in a special category entitled «The best invention in the field of nanotechnologies» for dental implants designed from bulk nanostructured titanium

Titanium is a material well suitable for production of implants for various purposes: in traumatic surgery, maxillofacial surgery, orthopedy, and dentistry. It is corrosion-resistant and has a low specific weight; therefore, articles made of this material have high strength and a comparatively small weight. Titanium does not exert any toxic, allergenic, or carcinogenic effects on the human organism and does not induce any inflammatory reactions in the ambient tissues.

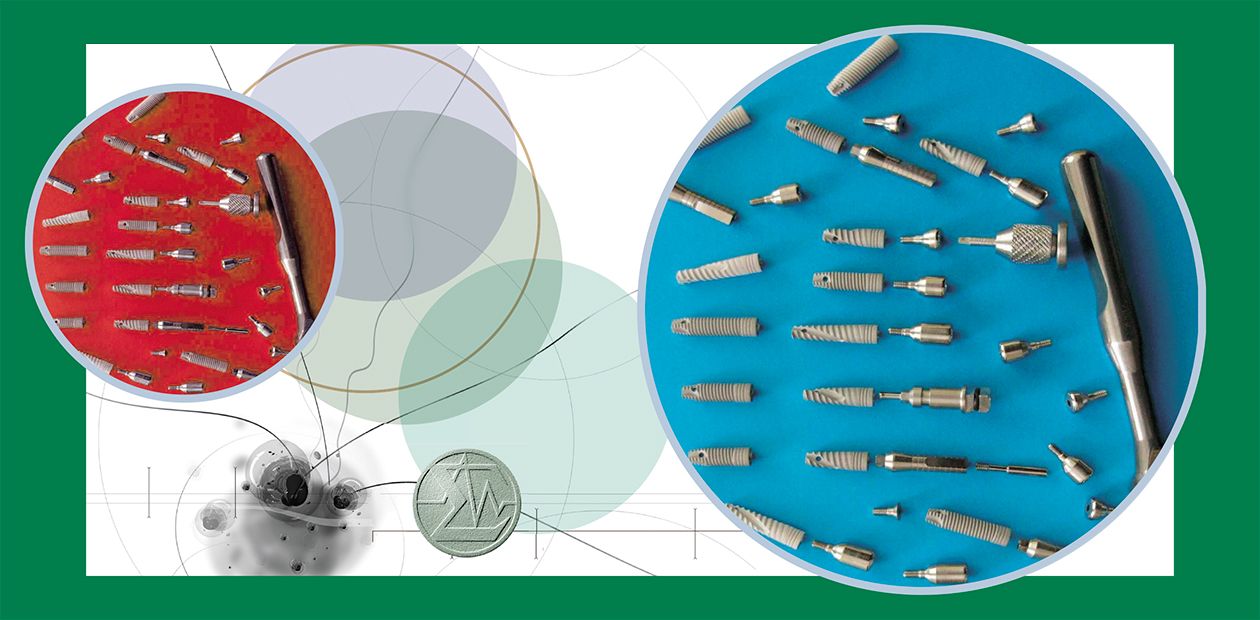

The Institute of Strength Physics and Materials Science was the principal organization in the team that designed specific dental implants. The implants were made of the VT1-0 nanostructured titanium. The nanostructured state in titanium was produced with the help of severe plastic deformation. The resultant material is comparable in its properties with titanium alloys used in medicine, but it is free from alloyed elements harmful for the human organism, such as aluminum, vanadium, and molybdenum.

The implants can also be covered with a special bioactive resorbed calcium-phosphate coating, which assists in bone formation without causing inflammation. This coating is formed by microarc oxidation of the implant surface on the MicroArc-3.0 device developed at the institute.

Specific features of the structure are responsible for some advantages of the implants: initial stability during introduction into the bone tissue, reduction of the implantation operation duration and of the degree of bone tissue injury, dense contact between the bone tissue and the implant surface, and capillary filling of the structural elements with blood. As a result, the engraftment period becomes much shorter: by 30 % for operations on the lower jaw and by 15 % for operations on the upper jaw.

In Russia, the authors’ rights for the new-type implants are protected by patents. Preparation of the initial stage of the production process has been completed: now the institute has departments of severe plastic deformation for obtaining nanostructured titanium bars and microarc oxidation for coating formation. The tentative cost of one implant will be 2,000 rubles, which is substantially lower than the cost of foreign analogs.

References

Sharkeev Yu. P., Danilov V. I., Eroshenko A. Yu., et al. Specific features of the structure and strain-induced behavior of bulk nanostructured titanium obtained under severe plastic deformation // Deform. Razrush. Mater. 2007. No.7. P. 27—31