Deep Processing of Feedstock for Petrochemistry

Novel bizeolite catalysts for cracking of hydrocarbon feedstock have been developed at the Institute of Hydrocarbon Conversion Problems SB RAS (Omsk)

Petrochemical industry is one of the most important science-intensive branches of modern industry. The cost of petrochemical products exceeds that of crude oil by a factor of 7—9. Meanwhile, motor fuels are only two to three times more expensive than crude oil.

Petrochemistry is based on the monomer production processes. These monomers are ethylene – for polyethylene, propylene – for polypropylene, butylenes – for rubber, etc. The monomers are obtained mostly by pyrolysis, catalytic cracking and dehydrogenation.

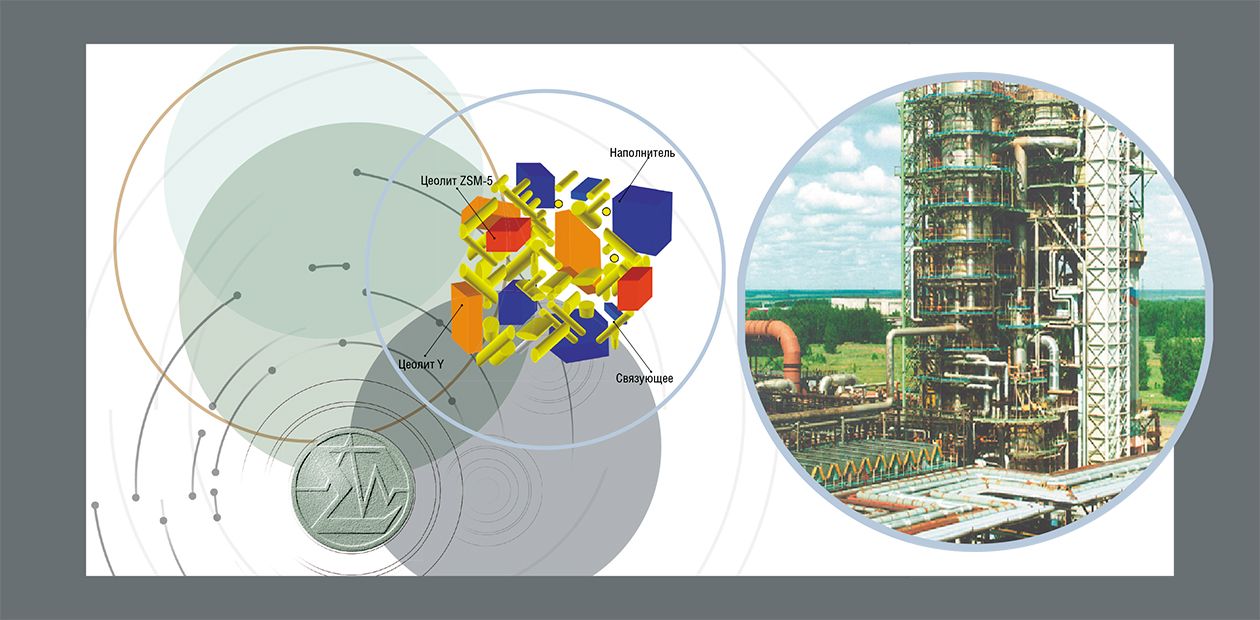

In the last decade, the leading oil companies of the world work on the development of a deep catalytic cracking process. It is the most economically efficient process for production of light paraffins (mostly propylene and butylene) from various hydrocarbons. A specific feature of this process is the application of novel bizeolite cracking catalysts.

The experiments carried out at the Institute of Hydrocarbon Conversion Problems SB RAS allowed us to develop a spectrum of bizeolite cracking catalysts. Depending on the oil conversion problems, these catalysts yield the following main products after the catalytic cracking of residual oil fractions:

– traditional catalytic cracking (the catalyst has been applied in industry): gasoline – 56—57%, light olefins – 11—12 wt. %;

– deep catalytic cracking: gasoline – 30—35%, light olefins – 35—38 wt. %.

This process is based on the application of special cationic forms of zeolites Y and ZSM-5, a highly active aluminosilicate catalyst matrix for preliminary cracking of hydrocarbon molecules with 30—60 carbon atoms. The zeolites carry out secondary reactions for production of light olefins with 2—4 carbon atoms.

The development, application and operation of the catalysts for traditional catalytic cracking were rewarded with the Russian Government prize for Science and Technology. Practical application of the new catalysts developed at the Institute has already begun at OJSC Gazprom Neft – Omsk Refinery.

References

Doronin V. P., Sorokina T. P. Chemical design of cracking catalysts // Rossiiskii Khimicheskii Zhurnal (Russian Chemical Journal), 2007. V. 51. Iss. 4. P. 23—29.

Doronin V. P., Sorokina T. P., Duplyakin V. K. // Catalysis in industry (Kataliz v Promyshlennosti), 2003. Iss. 2. P. 37—42.