New Features of Laser Welding

A pioneering idea has been put forward to perform laser welding adding active nanopowders and using resonance ultrasonic oscillations to improve the joint structure whose quality becomes commensurable with the basic material in terms of strength characteristics

There are various types of welding available at the moment. In all cases, however, the strength of the welded joint is lower than that of the basic material. This problem is solved in each particular case and acceptable results are reached, but the problem in general still persists.

Is it possible to reach the joint strength commensurable with the strength of the basic material? The answer is positive if one can solve the main problem: provide a high quality of the material inside the joint and prevent the formation of complicated dendrite structures and pores (gas bubbles) in the course of crystallization.

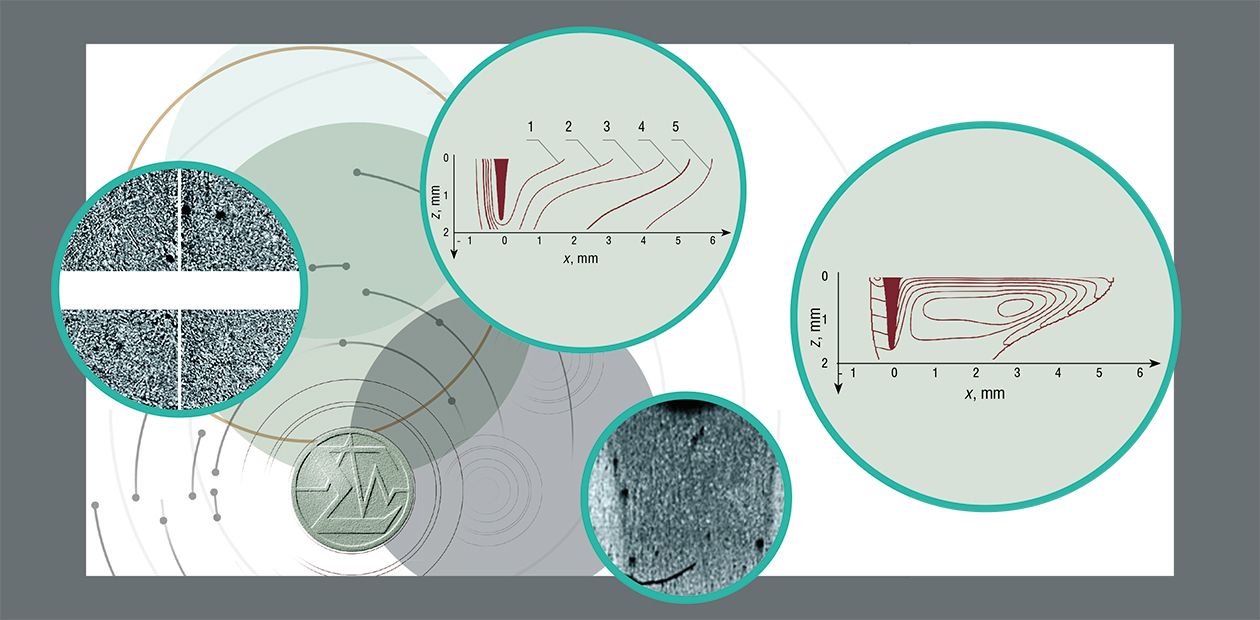

In contrast to conventional welding, the moving laser beam does not melt the metal, but squeezes it out, forming something like a welding bath where it is possible to create a material with required properties (including structural properties). If special nanopowder is added to this bath, its particles act as crystallization centers preventing the emergence of destructive crystalline structures. If there are many crystallization centers, the structure of the joint material becomes finer. The laser beam motion favors thorough mixing of the nanopowder over the entire joint depth. In this process, all characteristics of this material drastically change, the joint strength becoming commensurable with the strength of the basic material and sometimes even better. Nanoparticles to be introduced are prepared in a special manner and are activated to act as future crystallization centers.

The use of ultrasound leads to melt refinement and densification of the melt structure in the welding bath; moreover, gas bubbles formed in the course of crystallization are removed. Numerical modeling of the behavior of gas bubbles in the bath revealed the range of their resonant frequencies. Effective implosion of bubbles occurs in appropriate ultrasonic regimes.

Experimental studies of the ultrasound effect on improving the plastic properties of compounds were performed at the Khristianovich Institute of Theoretical and Applied Mechanics of the Siberian Branch of the Russian Academy of Sciences. Under the action of ultrasound, the yield stress and the resistance to fracture did not display any noticeable changes, but plasticity increased by more than 20 %.

The experiments performed show that the use of nanopowders and ultrasound for improving the joint structure leads to formation of joints whose strength (including fatigue strength) is commensurable with that of the basic material. These results may revolutionize many branches of industry.

References

Afonin Yu. V., Malikov A. G., Orishich A. M., and Cherepanov A. N. Laser welding of low-carbon steel // III All-Russian Conference “Interaction of high-concentration energy flows with materials in advanced technologies and medicine”, March 16—19, 2009. Novosibirsk, 2009. P. 7—8.

Cherepanov A. N., Afonin Yu. V., Malikov A. G., Orishich A. M. Application of nanopowders of refractory compounds in laser treatment of materials // Tyazh. Mashinostr. 2008. No. 4. P. 24—26.