Nano for Space

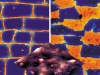

In #2 (14), 2007, “Science First Hand” wrote about the discovery made by Tomsk scientists: the effect of a “chess board” in mechanical stress distribution at the interface of two media. Eighteen months later, experts from the Institute of Strength Physics and Materials Science SB RAS (Tomsk) together with the Keldysh Research Center (Moscow) used this effect as the base for designing nanostructured heat-resistant coatings for rocket-space technology.

Modern constructions representing complex functional systems often have to work under extreme conditions. In rocket-space industry these conditions are super-extreme.

As there is no natural material that would be able to sustain the high temperatures of plasma flows, scientists and engineers have no choice but to create such materials. The lifetime of these materials, however, is very limited. Increasing it as much as possible as well as raising even more the plasma temperature, which determines the rocket traction, is a topical problem.

What are the specifications of the material from which a rocket jet is made? On the one hand, it should effectively retract the heat of a plasma flow so that the construction would not melt; on the other hand, it should not directly touch plasma. Highly heat-conducting copper is ordinarily used as a material for the jet; in addition, a system of inner water-cooling is provided. The outer surface of the jet is covered with heat-resistant ceramics. It is here that the materials specialists face a bundle of problems at the junction of physics, mechanics, chemistry, and nano-material science.

Due to the difference of the thermal dilatation coefficients of copper and ceramics, a very complex mode of deformation appears at their interface. In ceramics, a net of cracks forms and the material is partially exfoliated, which drastically limits the lifetime of a rocket. Evidently, at the time when programs of interplanetary travels and multiuse rockets are being developed the problem of engine efficiency and commercial effectiveness becomes pressing.

The answers to the topical problems of modern materials science are given by the new science branch supported in SB RAS – physical mesomechanics. Its methods allow calculations of mechanical stress at the interface of dissimilar media. Active studies into the effect of “chess board” distribution of mechanical stresses discovered two years ago have led to a very important conclusion: heat-resistant coatings applied to rocket jets should be nanostructural.

It is generally accepted that exfoliation of the coating from a substrate is related to poor adhesion. It is a serious but not the main problem. Calculations show that the net of cracks in the ceramic coating develops at the interface, on the edges of cells of “chess board” distribution of normal tension and compression stresses. Subsequent exfoliation of the coating takes place in the cells experiencing normal tension stresses. These are to be decreased, and physical mesomechanics answers the question how this can be achieved.

Without going into detail, let us present the main conclusion: the coatings must be multilayered and nanostructured. It provides the minimal amplitude of modulation of normal and shear stresses at all interfaces of the multilayered coating, which helps to improve cardinally its performance parameters.

No less important is the following problem: how to keep the coating’s nanostructure at high temperatures? A stable solid body by its nature tends to be the perfect crystal. Nanostructure is not characteristic of a solid body and under high-energy influence it rearranges into a monocrystal. Physical mesomechanics solves the problem of nanostructure stabilization by segregating, within the structure, nanoparticles of high-melting compounds of a certain type.

Specialists from the Institute of Strength Physics and Materials Science have designed the nanotechnologies of layer-on-layer deposition of coating with bombarding each layer with a beam of ions. It has turned out that preliminary nanostructuring of a substrate with the beam of ions decreases significantly the average grain size in the coating – up to 10—20 nm – whereas hardness, wear-resistance, and thermal-cycling stability of the coating increase manifold.

The optimal chemical composition of multicomponent nanostructural coatings was determined, and the technology of formation in them of controlled distribution of phases by alternate deposition-bombarding of layers in a single vacuum cycle was developed.

Firing tests of the new coatings were conducted at the Keldysh Center, on a megawatt class plasmatron. A sample with the nanostructured multilayered coating went through a number of firing cycles. Under the conditions of axial impact of the powerful plasma flow, standard heat-resistant coating experienced circular exfoliations. The nanostructured coating designed by the research group from the Institute of Strength Physics and Materials Science and Keldysh Center preserved its structure and heat-resistant properties.

What are the collaborators from Tomsk and Moscow working on now? They have revealed new effects of self-organization of structures of multilayered coatings at high temperatures, which allow creation of smart coatings. It is a crucial stage in developing new generation materials. As for the technology, it is necessary to fine-tune the operations of deposition of these coatings on real rocket-space constructions. The problems are complicated, but the main thing has been done: a solid foundation for further scientific research has been laid.