Nanostructural COATINGS: "Chessboard" Effect

Despite impressive advances achieved in the field of “nanomaterial science,” there are severe difficulties on the way of creating voluminous nanostructural materials, their welded joints, and complex configurations. No technologies are available for creating a uniform nanostructure in large volumes of material; there is a problem to preserve the nanostructure in welded joints and a problem related to a drastic decrease in the strength of nanostructural materials in zones of local overloading.

However, there is an approach to solving these problems that involves special nanostructuring of only surface layers of structural materials. The scientific basis for such technologies was developed at the Institute of Strength Physics and Material Sciences of the Siberian Branch of the Russian Academy of Sciences; the necessary equipment was also designed there. This became possible owing to a discovery made in studying the formation of nanostructures in multilayer surface layers and coatings. The essence of this discovery is as follows. At the interface of two media, a special regular structure is formed; the character and parameters of this structure are responsible for new properties acquired by the sample tested.

New nanostructural materials are being intensely developed in all countries with a high level of science and technology. Good characteristics of strength, wear resistance, fatigue strength, and corrosion resistance allow these materials to occupy a dominating place in material science of the 21st century.

At the interface

It should be noted that the interface of any different media with different elasticity moduli, thermal expansion coefficients, and chemical compositions under external actions is characterized by nonuniform distributions of stresses, strains, and chemical potential.

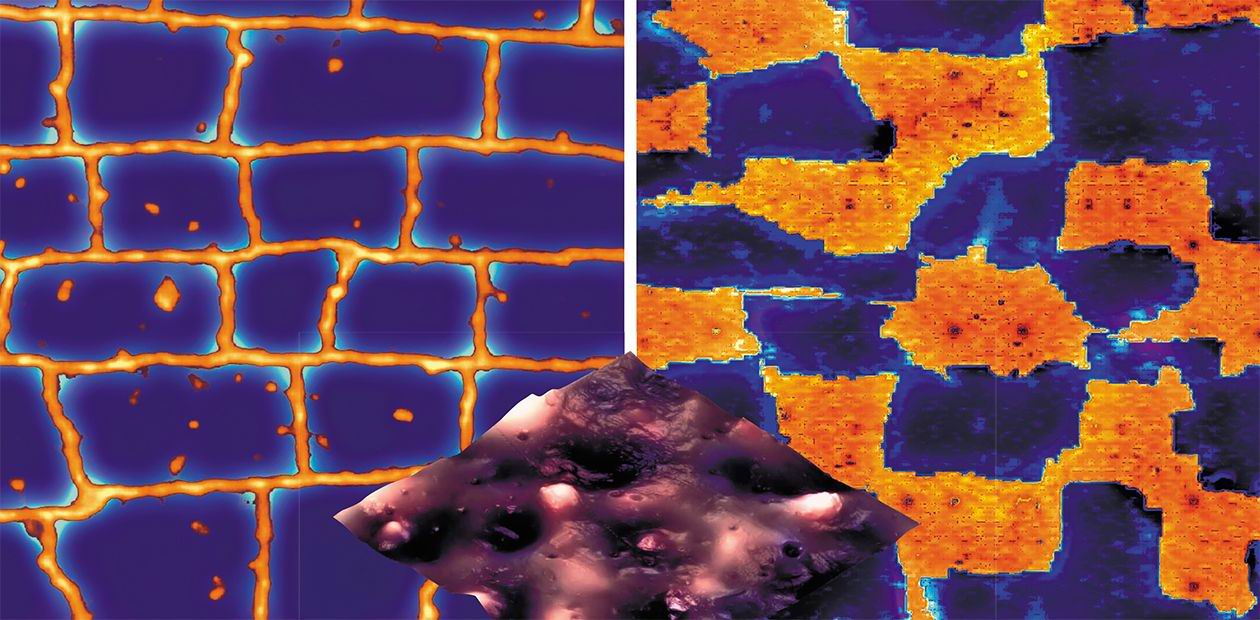

Experimental research and theoretical calculations showed that the distributions of stresses and strains on the interfaces in solids are periodic. For a planar interface, this distribution resembles a “chessboard,” in which cells experiencing compressive normal stresses alternate with cells experiencing tensile normal stresses. Shear stresses also have a staggered distribution, but the phase of the latter is shifted in space by π/2.

2005. “Chessboard” effect in the stress and strain distributions on the “surface layer-substrate” interface was experimentally demonstrated

The influence of this effect on the strength characteristics of the sample can be explained by considering the mechanisms of the plastic flow and failure of a solid loaded above its yield point. This is determined by the local loss of shear stability; therefore, the key problem in the methodology of description of plastic flow and failure of solids is system analysis of the shear stability of all possible subsystems in the loaded material.

It is known that the surface layer in a loaded solid has the least shear stability; this layer can be considered as a special state of matter. In physical mesomechanics, it is even recognized as an independent subsystem. The “native” and nanostructured surface layers respond differently to dislocations (defects). In the first case, the surface layer acts as a pump pumping dislocations into the loaded material and accelerating the material failure. The nanostructured surface layer can be called an “inverted pump,” which delays accumulation of deformation defects in the bulk of the material, thus increasing its service life.

Plastic strains in solids can only originate and propagate in zones of tensile normal stresses. It is in these zones that conditions required for the generation and propagation of dislocation nuclei (or any other defects of the crystal lattice) are formed. Hence, it turns out that the staggered character of the distribution of tensile normal stresses at the interface between the surface layer and the substrate is responsible for the mosaic localization of plastic shear nucleation in the surface layer of the deformable material.

The smaller the size of the strain-localization areas, the greater the volume of the material involved into the plastic flow and the higher the mechanical strength characteristics of the loaded material. A more uniform distribution of stresses generated in the sample prevents the emergence of stress macroconcentrators where a large crack arises and the material failure begins.

Strength and lifetime

Nanostructuring of the surface layers of loaded solids and application of nanostructural coatings with allowance for the “chessboard” effect can become an efficient method for material hardening. This idea was verified and validated experimentally at the Institute of Strength Physics and Material Sciences. Moreover, the operational parameters of tool materials can be additionally improved by using multilayered nanostructuring of the surface layers of the material: first, substrate nanostructuring and then application of the coating itself.

Several methods of nanostructuring of the surface layers of structural materials have been developed at the Institute; changes in micromechanical characteristics of various steels and alloys based on Ti, Al, and Ni, with the surface layers nanostructured by ultrasonic impact treatment, have been studied in detail. The results of these works demonstrate that it is possible to improve significantly macromechanical characteristics of a material without changing the composition of the surface layer. Nanostructuring of welded joints of high-strength steels and alloys is particularly efficient. Their characteristics, including fatigue strength, can be multiply increased.

The intermetallic and chemical compounds that possess very high hardness are of special interest. Their high thermodynamic stability, however, makes difficult the nanostructure formation. This difficulty can be overcome by various methods. First, it is possible to use multispecies compositions where mixtures of several compounds of different configurations can be formed. Second, it is possible to use an extremely fine staggered structure of the coating-substrate interface, which allows the clusters of compounds of different modifications to be synthesized in cells with tensile normal stresses and their interfaces to be confined to cells with compressive normal stresses.

In addition, it is possible to expose the deposited coating to high-energy beams of gas ions, which favor the distribution of clusters of different compositions over the “chessboard” cells on the coating-substrate interface.

Based on this research, the Institute has developed nanotechnologies for application of superhard nanostructural coatings onto materials of versatile structural and instrumental purposes. Expanding the application of these results in industry should become a fact of today rather than of distant future.

V. E. Panin, academician of the Russian Academy of Sciences, V. P. Sergeev, candidate of physics and mathematics (Institute of Strength Physics and Material Science, Siberian Branch, Russian Academy of Sciences, Tomsk Scientific Center)