Reversible Electrostatic "Glue"

At the Institute of Automatics and Electrometry SB RAS (Novosibirsk) principles and technology of the highly effective cohesion of surfaces with the help of an electric field have been developed.

All glues are based on the two physical phenomena—adhesion (from Lat. adhaesio) and cohesion (from Lat. cohaesus). Underlying them are the forces of intermolecular interaction (Van der Waals forces). To be highly adhesive, a glue should have good fluidity. Nearly all known glues—cyanoacrylate, acrylic, silicone, polyurethane, epoxy, UV-set—have a liquid component. Its setting, which provides high cohesion, occurs in the second stage of bonding—polymerization—which may take up to several hours.

Is it possible to break the bond without damaging the surface? When polymerization is complete, it is usually impossible. However, there are exceptions: reversible glues. They include, for example, thermal glues—polymers that become liquid when heated and set when cooled. This process is completely reversible, but it is of great persistence, and every time it requires a great thermal energy to carry it out.

Physicists from the Institute of Automatics and Electrometry SB RAS have developed a principally new technological solution to the problem of bonding the solid bodies’ surfaces. The laboratory of thin-films ferroelectric structures has created the technology of the reversible quick-acting “bonding” of the surfaces without a liquid medium—with the help of the energy of an electrostatic field. The object of the study is the thin-films structures, which are new for microelectronics: metal (semiconductor)—ferroelectric—removable electrode.

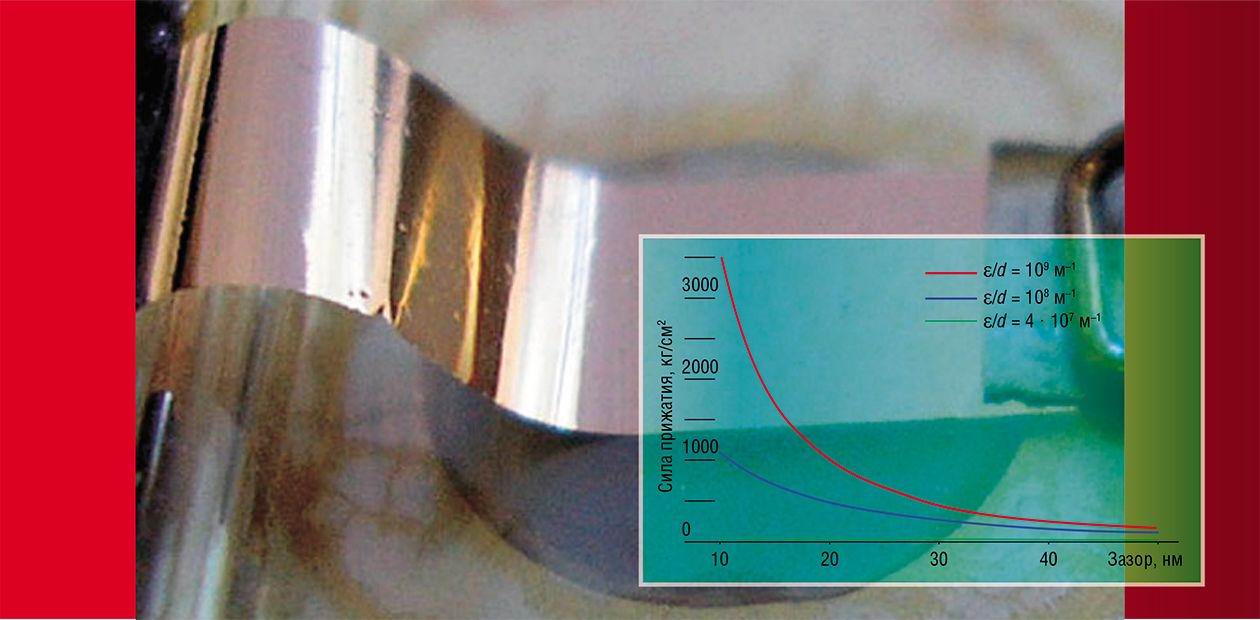

As is known, ferroelectrics are characterized by very high dielectric permeability: for example, for the ferroelectric film (FF) of barium-strontium niobate (BSN) it goes as high as 1,000—5,000. This high value determines such distribution of an electric field in the structure when voltage is applied to it that the main part of potential is applied to the air gap between the removable electrode and the FF. As voltage grows, the gap lessens nonlinearly (due to the pressing of elastic thin electrode), down to 5—100 nm depending on the roughness of the ferroelectric surface. Thus, it is to the removable electrode that almost all electrostatic force is applied, and the smaller the gap, the higher the pressing force.

We have managed to create mechanic contact with the force of attraction of the surfaces up to 1000 kg/cm2 and more, in a really working structure (barium-strontium niobate, lanthanum modified, as ferroelectric; sapphire as substrate; beryllium bronze as removable electrode) in a very short time (microseconds) with the help of a 10—100 voltage. The time of the contact break is less than 1 microsecond.

We should underline that for usual dielectrics the drop in voltage on the nanometric gap is insignificant, and the effect is absent. The following facts are of importance: (a) it is possible to apply high voltage to the nanometric gap without breakdown, (electric strength of the used FF is fairly high), and (b) poor accumulation of charge in the film when the field is in effect and its fast relaxation when the voltage impulse is off (determined by the high quality of the crystal structure of FF).

Let us note that the characteristics of cyanoacrylate with its highest breaking strength among traditional glues exceed the mechanical characteristics of the studied structure almost ten-fold. However, “electronic glue” developed in the Institute of Automatics and Electrometry SB RAS features such unquestionable advantages as operation speed and reversibility. The main field of using the product is microelectromechanic systems (MEMS): micromotors, fast-acting microvalves, microoptics, pressure sensors, micropumps, etc.