Plant

820

The Angarsk Electrolysis Chemical Complex (AECC) yielded its first product — enriched uranium-235 — on October 21, 1957. This day is considered the birthday of AECC. Till the mid-1980s, the plant belonged to the system of military defence of the USSR, it took part in the production of “military” enriched uranium used in atomic bombs, forged the atomic shield of our Motherland. However, in the second half of the 1980s, the Complex was given orders to shift to production of peaceful uranium-235 hexafluoride of a low degree of enrichment, raw material from which other plants make nuclear fuel for power stations. In 2007 AECC celebrated its 50th anniversary not only to remind that 50 years ago its first facilities started to work, but also to recollect and to express deep gratitude to the scientists, engineers, technicians, and workers whose fate was to come here first from other places of Russia and to take part in the construction of the giant nuclear facility in remote Siberia, in the midst of pristine taiga. This was a great victory.

Half a century ago, they joined their efforts to cope with the enormous task of creating a very big high-tech plant in a most challenging environment, and succeeded in doing this in less than four years after the governmental decision of 1954

In July 1954, the newly-appointed first Director of the AECC V. F. Novokshonov felled the first pine in the taiga near the city of Irkutsk, to mark the start of construction of the unique nuclear complex which was at that time called “Post-Office Box 79”. In three years it was put into operation.

This was remarkably fast for starting the production of an absolutely new type. Many young people of that time felt a strong attraction to Siberia, especially to the famous Lake Baikal, jewel of our Irkutsk Oblast. This was a mass movement headed by Komsomol (Young Communists’ League). Young people came to build, and then to work at the Angarsk Oil Refinery Plant, at the Bratsk Pulp and Paper Plant, at the Bratsk Hydroelectric Power Station (at that time the world’s greatest one), Bratsk Aluminum Plant, as well as at the AECC. The latter was built quietly, without a fuss. The numerous large industries were placed in this region because a cascade of giant electric power stations on the Angara River could provide huge amounts of electric energy. To start the production at the AECC ahead of the schedule, a dedicated coal-burning electric power station CEPS-10 was built having a capacity of more than 1 gigawatt. It was one of the most advanced Soviet heat-power stations. Somewhat later, a unique high-voltage (500 kV) electric power line connected the AECC with the Bratsk Hydro-Electric Power Station. The AECC was a highest-priority project. Minsredmash — the Atomic Energy Ministry of the USSR — was called the “state within the state”. It raised all available resources to complete erection of the Soviet nuclear shield. Today, it is not a secret that soon after the World War II was over the USA prepared a plan of dropping atomic bombs on 18 cities of the USSR. This list soon increased to 30, and finally to 100 cities. Hiroshima and Nagasaki were regarded as a successful experiment. There was an urgent need to withstand the threat of a nuclear war. Most of those who came to build the complex were young people who had served in the army and navy.

In 1963, the first full-scale uranium isotopes separation plant was put into operation. The separation was based on diffusion through porous membranes. Its demand for energy was 1.5 Gwt, about 4 % of all the electric energy then produced in the Soviet Union!

“October 6, 1955. Forty-five hundred soldiers arrived to take part in the construction project. The conditions are harsh: no proper warm clothes, no steam bath, freezing cold in the barracks”

“October 10, 1955 …2,400 prisoners are working at the construction site”

(From the diary of V. F. Novokshenov, the first Director of the Complex)

“1958 …When we began building the chemical plant, there was nothing but a forest on the construction site. We made a forest cutting, a prisoners’ camp, and a barbed wire corridor to bring inmates directly from the camp to the Complex construction site. Up to 1,500 people per shift worked on this site alone. All in all, there were dozens of thousands of workers, mostly prisoners and military servants… The atmosphere was healthy, thanks to Director V. F. Novokshenov. He respected constructors who spared neither effort, nor time or health; in spite of all the difficulties, they were building the future Complex and mounting absolutely unique equipment that existed nowhere else”

(by Yu. I. Avdeev, former head of AUS-16 Construction Company, the Honored Constructor of the Russian Federation)

In 2007, fifty years passed since the AECC produced its first enriched uranium-235. From 1957 the complex operated as a defense enterprise; later, it switched to making uranium for power stations alone. In 1997,

a decree was issued according to which this kind of activity had to be licensed. The license granted by Rosatomnadzor (Federal Atomic Control Agency) and renewed last year by Rostekhnadzor (Federal Environmental, Technological and Nuclear Inspection Service) authorizes production of enriched uranium with 5 % maximum content of isotope 235, for the needs of nuclear power stations. Uranium used in weapons contains at least 90 % of isotope 235, and nuclear fuel for ships requires 20 %. However, the AECC has never made products of such a high extent of enrichment, the maximum enrichment was 6.5 %. Uranium of a low extent of enrichment was transported to other companies based in closed nuclear towns and settlements, for further enrichment. The Soviet Union established a system for gradual uranium enrichment with isotope 235, depending on demand.

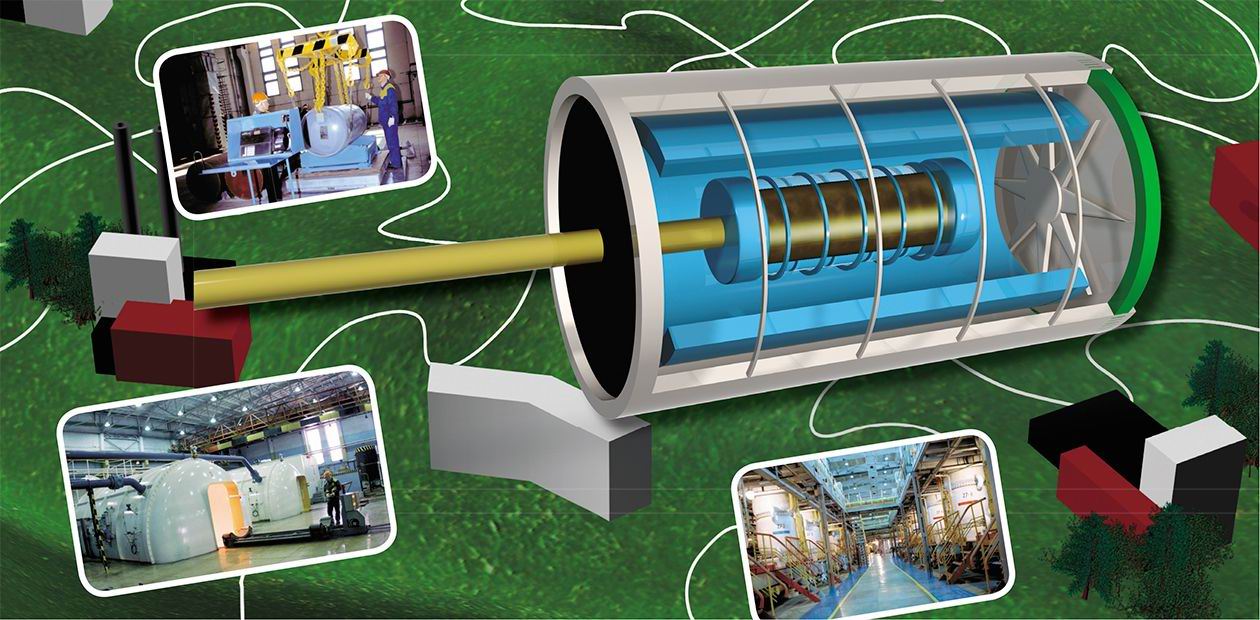

Originally, uranium isotopes in the form of uranium hexafluoride were separated using the gas diffusion technique. Power-consuming and cumbersome diffusion equipment occupied four buildings whose total length was 4 kilometers. Running of the equipment heated the air indoors to over 40 degrees Celsius and produced strong noise.

Transition to the new centrifugal technology of uranium isotope separation improved working conditions, reduced energy consumption to one-tenth of the former amount, lowered the cost of enriched uranium hexafluoride, and dramatically cut down the consumption of cooling water.

At the end of the 20th and beginning of the 21st century, the Complex was on the upswing, both in terms of creativity and production, which was attributed to massive introduction of up-to-date, reliable, and environmentally-safe technologies for uranium isotopes separation in the new-generation super-high-speed centrifuges — unique machines that have no rivals in the world

With the collapse of the USSR, Russia lost direct access to important sources of uranium ore, such as those found in Middle Asia and especially in Kazakhstan. This is an important argument in favor of having an international uranium enrichment centre. For over a year, the possibility of establishing such a centre on the basis of the AECC has been discussed. This choice is attributed, in part, to the fact that the Angarsk Complex was shifted from the “top secret” to a mere “secret” category. Also, as the gas diffusion plant shut down, some vacant production premises appeared. The Complex has its own training center which provides training and refresher courses to specialists and trains Russian and foreign citizens. The initiative of organizing an International Uranium Enrichment Centre belongs to Russia. The Center’s mission would be to facilitate control over dangerous situations emerging throughout the world, like development of uranium-enrichment technologies by Iran, as these might be used both in nuclear power industry and in arms production.

Such a center would help its members to develop their own nuclear power industry without access to the uranium enrichment technologies, which would rule out the possibility of making nuclear weapons in member countries. At present, an inter-governmental agreement has been signed between Russia and Kazakhstan on co-operation in establishing the International Uranium Enrichment Centre. Potential partners are Ukraine, Belgium, Armenia and, possibly, Finland.

If a partner makes a decision to build a nuclear power station, a site should be prepared and appraisal should be carried out. On the average, it takes five years to start a station. A pre-requisite for the project’s success is guaranteed fuel delivery. Control procedures on the part of the International Nuclear Agency should be specified, as well as guarantees ensuring that uranium will be used solely for peaceful purposes. It is quite feasible to check the quantity of imported, processed, and exported materials without looking deep into their production technologies. For the time being, seven inspectors have visited and studied the Complex — certainly, within the security regulations applied to foreign specialists. Preparation of security clearance papers takes about two months.

Russia’s current uranium enrichment output amounts to 40% of the world’s production. This satisfies completely national demand for fuel for nuclear power industry and allows us to render services on uranium enrichment and delivery of enriched uranium to other countries — mostly, but not exclusively, to the companies built in the Soviet times in the former USSR republics. Efficient technologies give us an advantage over competitors in terms of price. The Complex has been supplying its products to the international market for over 30 years.

Aleksander A. Kozlov and I came to the Complex’s construction site almost at the same time, in 1960. I came to prepare my graduation project, and Aleksander had just got a degree. He was from Ural Polytechnic Institute, and I from Moscow Institute of Engineering and Physics. The main department of my Institute was headed by Academician Mikhail D. Millionshchikov. He was also Chairman of the Inter-Departmental Commission charged with acceptance of equipment made by a number of producers, including the Angarsk Separator Plant. I discussed with him my future career.

I come from Dneprodzerzhinsk, the motherland of stagnation (Leonid Brezhnev, General Secretary of the USSR Communist Party, came from Dneprodzerzhinsk – SFH). I could go back, to the Dzerzhinsky Metallurgical Plant, stay at the Kurchatov Institute in Moscow, or go to Siberia. In Siberia, I could choose between Krasnoyarsk, Angarsk, and Krasnoyarsk-26. Millionshchikov said, “You should go to Angarsk: a plant is being built there and the prospects are good.”

In the fifty years that had passed since then we worked hard, and to our satisfaction. Even though we live in taiga, we have managed to print a book called Fifty years in the Ranks and to shoot a film Half a Century in the Ranks. They are about the people and about our Complex. We dedicated the book to the VICTORY won by those people, because to build such a plant in three years was a heroic deed. The complex was built by the people who worked with full dedication to carry out the task assigned to them by their Motherland (V. P. Shopen)

Twenty years ago Russia was 10—15 years ahead of the USA in technologies of uranium enrichment. Researchers, however, are on the alert: for instance, the company URENCO that unites three states — Holland, Germany, and Great Britain — has also mastered industrial application of the centrifugal technique of isotope separation. According to our data, their isotopes are not inferior to ours. The search is going on: Russia is now running 8th-generation machinery, and Rosatom’s research institutes and design bureaus are developing 9th- and 10th-generation machinery and equipment with a view to increasing productivity and reducing power costs.

By the way, not only types of activities but also the top managers who are in charge of our facilities must be licensed. I obtained a license for managing a nuclear fuel enterprise in 1985, when in the position of Chief Engineer. Today, a top manager’s performance is reviewed once in five years: if you pass an exam, you are granted the license that certifies your qualification to manage. My license expires in March 2008. Our personal appraisal is performed by Rostekhnadzor top managers. We are getting ready for it, as the attitude towards licensing top management of such companies is extremely demanding.