BIOPLASTOTAN: Compatible with Life

Ekaterina Shishatskaya, senior researcher of the Institute of Biophysics, Siberian Branch, Russian Academy of Sciences (Krasnoyarsk), became one of the winners of the 2010 competition for the highly-regarded State Prize in Science and Innovation for Young Scientists. The research of the 35-year-old Doctor of Biology is devoted to the development of high-tech biomedical items from destructible polymers and development of a scientific basis for their practical application. Today these "plastics", compatible with live organisms and able to be destroyed without releasing any toxic substances, are received with the help of microorganisms.

The studies on the development of a new class of biodestructible polymers have been carried out at the Institute of Biophysics SB RAS: the Institute runs the first in the country unique pilot plant which makes this promising material. The polymer synthesized by the Krasnoyarsk scientists has already obtained its trademark - Bioplastotan. Currently, the new material undergoes active laboratory tests, though there are all reasons to believe that in the nearest future it will take a deserved place in surgery and transplantology.

Wide-range pre-clinical tests have already proven that articles made from Bioplastotan meet the requirements imposed on medical materials and products and that they can be efficiently applied for reconstruction of tissue defects, in endoprothetic devices, as seam materials and in other medical applications.

On February 8, 2010, on the Day of Russian Science, President of Russia Dmitry Medvedev presented in the Kremlin the highly-regarded State Prize in Science and Innovation for Young Scientists to Ekaterina Shishatskaya, senior researcher of the Institute of Biophysics, Siberian Branch, Russian Academy of Sciences (Krasnoyarsk).

The research of the 35-year-old Doctor of Biology is devoted to the development of high-tech biomedical items from destructible polymers and development of a scientific basis for their practical application.

The studies on the development of a new class of biodestructible polymers have been carried out at the Institute of Biophysics for many years under the leadership of Doctor of Biology T. G. Volova. The polymer synthesized by the Krasnoyarsk scientists has already obtained its trademark – Bioplastotan. Currently, the new material undergoes active laboratory tests, though there are all reasons to believe that in the nearest future it will take a deserved place in surgery and transplantology.

Ekaterina Shishatskaya has a degree in medicine and has been working on the problem of a polymer “compatible with life” since 1993. Her achievements brought her several prizes, including the Russian National Prize The Future of Seam Materials (2008), Academician Lavrentyev Prize (2008), and the L’Oreal-UNESCO National Fellowship For Women in Science (2009)

The word “biopolymers” is well-known today. The prefix “bio” here means that these natural analogs of common plastics are of a natural rather than of an artificial origin. They are created by living bacteria: in these organisms, biopolymers are accumulated as a natural product of cellular metabolism.

What are the advantages of these natural plastics? They are valued for a nonconventional property – a relatively short life time, and the ability to be destroyed without releasing any toxic substances. Thanks to these properties, biopolymers can be used for production of various goods, from ecological packing materials to surgical seam materials.

Today, a bottle made out of a biopolymer is too expensive, but this material has proved to in great demand in reconstruction medicine.

Biomeccano

A new rapidly developing area of modern science – tissue engineering – formed at the interface of biology and medicine. Its goal is to develop equivalents of human tissues required, among other things, for the construction of artificial organs.

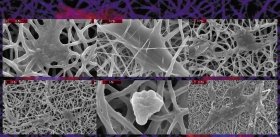

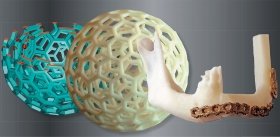

The creation of such tissues consists of several stages. Prepared cellular material is seeded onto the “supporting structure,” the so-called “scaffold. ” The scaffold-matrix is an analog of a natural extracellular matrix (ECM). The latter can consist of human or animal “tissue scaffolds” devoid of cells or their more or less successful analogs made of natural or synthetic materials. Naturally, for reconstruction of each tissue it is necessary to select its own adequate ECM equivalent. Then, the matrix has to be populated with the corresponding types of cells. After implantation into a living organism, the new tissue must be supplied with the necessary blood delivery and innervation.

Today, several companies in the world are engaged in investigating biopolymers of bacterial origin and in developing a technology for their production and practical application. In Russia, such studies are carried out at the Institute of Biophysics, SB RAS (Krasnoyarsk) – it is here that the technology for the production of polymers of hydroxyalkane acids with different chemical structures has been developed. The Institute runs the first in the country unique pilot plant which makes this promising materialThe approach described makes it possible to cope with the deficit of donor tissues and organs. The main problems in the solution of this task are the selection of the scaffold material for the future tissue and the creation of a necessary “matrix” with a certain structure specific for each type of tissues from this material.

The requirements to such material are very strict: it has to be absolutely safe for the organism, support the viability of cells planted on it and thus provide for their normal development into the necessary tissue. However, this is not all. With time, such material must undergo biodegradation (destruction) in the organism without forming any decomposition products that would be toxic for the cells and the organism, and be substituted with a genuine newly formed tissue.

These requirements are fully met by the materials under the collective name of Bioplastotan. The technology of their production was developed at the Institute of Biophysics, SB RAS, in Krasnoyarsk. Today, the bioplastic and the corresponding products for medical and biological purposes are produced at the institute’s pilot plant. To begin their production, the researchers working at the institute not only had to select the necessary microbe strains and optimum conditions for their growth, but also they had to industrialize the cultivation of autotroph bacteria and to develop a technology for separation of the necessary product from the biomass.

In concord with the organism

Today it is possible to declare with confidence that Bioplastotan has promising applications in reconstructive surgery and, in particular, in tissue engineering. This is confirmed by the results of numerous studies carried out by the Krasnoyarsk researchers and by other Russian and foreign scientists.

This biocompatible polymer obtained by the original technology of synthesis, extraction and purification developed by the author has the ability to decompose inside the organism, and the rate of its biodegradation can be controlled. Meanwhile, it is a durable material that can be used for the production of various items. Actually, a whole family of such specialized items with biomedical function has already been created.

The most obvious application of the new material is the production of sutures that dissolve with time in the living tissues without trace or consequences. The methods for physicochemical structural modification of the matrices made from Bioplastotan in the form of flexible films and membranes applicable for cellular technologies have already been developed. Bulk constructions and implants, including composites with ceramics, have been created to eliminate the defects in the bone and gristly tissues. Also, the new polymer has been used for the production of excellent stents – tubular endoprothetic devices used for reconstruction of blood vessels and bile ducts.

Another interesting area of research carried out by the Krasnoyarsk scientists is the development of the technology for application of biopolymers for deposition and controlled delivery of medicines. This is an important therapeutic problem. It is well-known that most of the medicine used goes out of the organism without reaching the target tissue or organ. In this respect, very promising are micro- and nanoscale particles made of a biopolymer. Such a capsule filled with a medicine gradually decomposes and releases the medicine with the desired rate and in the concentration necessary for effective treatment. These carriers can function in a living organism for prolonged time (depending on the way of their introduction), delivering the medicine in required time and at the precise “address.”

Wide-range pre-clinical tests have already proven that articles made from Bioplastotan meet the requirements imposed on medical materials and products and that they can be efficiently applied for reconstruction of tissue defects, in endoprothetic devices, as seam materials and in other medical applications. The clinical tests of the new biomedical products have already started and are highly successful. These results prove that the scientific and practical bases necessary for the introduction of the new promising biomaterial into medical practice have been created.

References

Biopolymers for Medicinal and Pharmaceutical Applications (Steinbüchel A. and Marchessault R. H. eds.). Hardcover: Handbook Wiley-VCH, Weinheim, 2005.

Deev R., Isaev A., Kochish A., Tikhilov R.. Paths of development of cellular technologies // Travmatologiya i ortopediya Rossii, 2008. V. 1(47). P. 65—74.

Hench L., Jones J. Biomaterials, artificial organs and tissue engineering // Woodhead Publishing Limited, Cambridge, 2005.

Shtilman M. I., Polymers for medico-biological applications // Akademkniga, Moscow, 2006.

Volova T. G., Sevastianov V. I., Shishatskaya E. I. Polyoxyalkanoates – biodegradable polymers for medicine. // Nauka, Novosibirsk, 2003; Platina, Krasnoyarsk, 2006.

The photos used in the publication are the courtesy of the press service of President of Russia, S. N. Churilov and V. T. Novikov